Alumina (Al₂O₃)

A versatile advanced ceramic material engineered for additive manufacturing and high-performance applications.

Adva Cera offers Alumina (Al₂O₃) as a core advanced ceramic material for additive manufacturing applications requiring durability, thermal stability, and electrical insulation. Alumina is one of the most widely used oxide ceramics due to its well-balanced mechanical, chemical, and electrical properties.

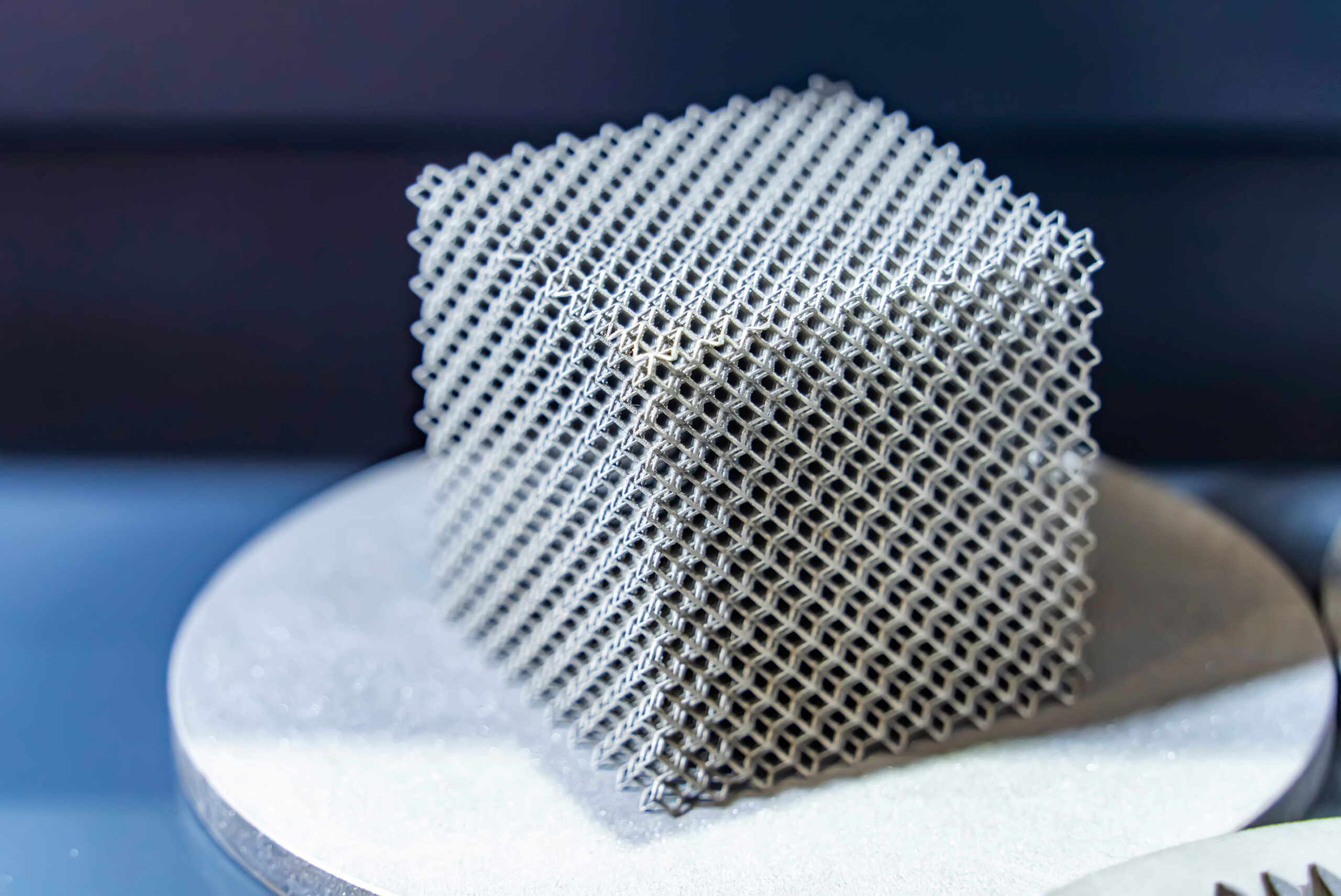

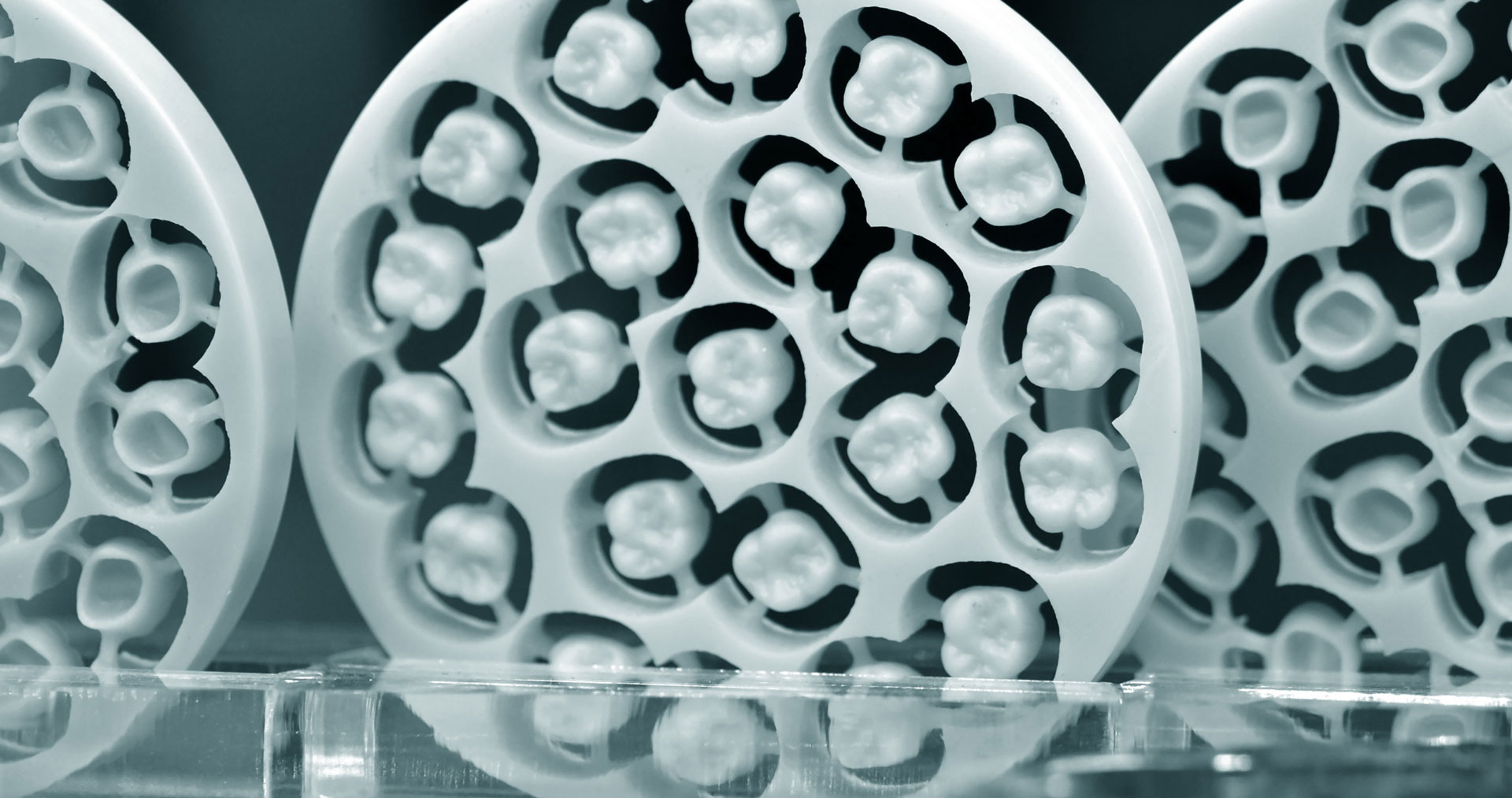

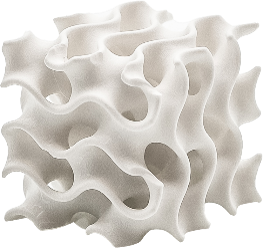

Through ceramic additive manufacturing, Alumina can be produced in complex geometries while maintaining consistent material performance. This enables engineers and product teams to design components that meet demanding operational requirements while benefiting from the design freedom of additive processes.

Alumina

Material Properties

Alumina is characterized by a combination of properties that make it suitable for a wide range of industrial, aerospace, electronics, and medical applications.

Key material attributes include:

These properties make Alumina a reliable choice for components exposed to mechanical stress, heat, or electrically sensitive conditions.

(303) 449-1457

Why Choose

Alumina for Additive Manufacturing

Additive manufacturing enables Alumina components to be produced with intricate geometries, internal features, and optimized designs that are difficult or impossible to achieve with traditional manufacturing methods.

By aligning material formulation, printing parameters, and sintering processes, AdvaCera ensures Alumina parts exhibit consistent density, mechanical integrity, and repeatable performance from prototype through production.

Applications of Alumina

Due to its versatility, Alumina supports applications across multiple industries where reliability and performance are critical.

Typical application areas include:

(303) 449-1457

Design Flexibility

With Alumina

The use of additive manufacturing expands how Alumina can be applied in real-world designs. Engineers can leverage complex shapes, reduced part count, and customized geometries while maintaining the material’s inherent performance characteristics.

This flexibility allows Alumina components to be tailored to specific application requirements without compromising durability or functionality.

Engineering Performance

With Alumina

By combining advanced material science with ceramic additive manufacturing, Alumina from Adva Cera supports reliable, high-performance solutions across a broad range of applications. From early development to production-ready components, Alumina remains a foundational material for advanced ceramic manufacturing.