Advanced Ceramics

Additive Materials Suited for Industrial Applications

Materials Innovation

Tailored to Your Specific Project Needs

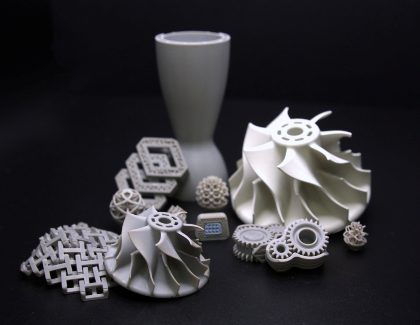

o Adva Cera delivers complex, Advanced Ceramic components that are additively manufactured according to precise, application-driven requirements. Our commitment to materials innovation goes beyond processing. From early-stage development through production qualification, we collaborate with OEMs, researchers, and other customers to develop ceramic systems that overcome their engineering challenges and withstand intensive performance demands.

Our Advanced Ceramics portfolio includes oxide and nitride formulations that are optimized for temperature resistance, chemical stability, and mechanical strength and bioceramics that are optimized for biocompatibility. All are validated for use in additive manufacturing workflows. By aligning material development with printing and thermal process development, Adva Cera ensures that our products are consistent, high-quality, and guaranteed to satisfy our customers.

“*” denotes a material that is still in development.

Oxides

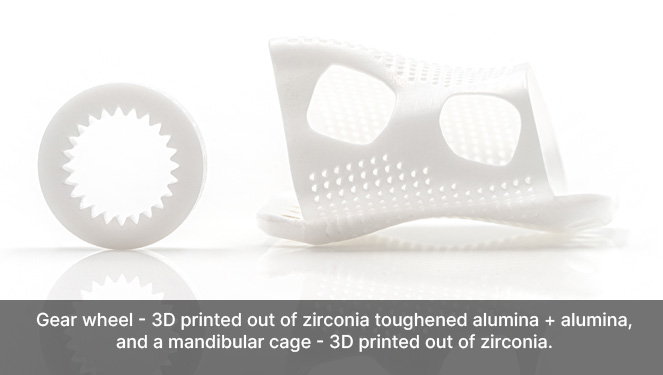

Alumina (Al2O3)

Alumina is one of the most commonly used ceramic materials, owing largely to its high hardness, thermal stability, and corrosion resistance. Components composed of alumina are electrically insulating and puncture-proof, making them suitable for use as substrates in electronics manufacturing.

Zirconia (ZrO2)

Zirconia, dubbed “ceramic steel,” offers a combination of high hardness, wear and corrosion resistance, and one of the highest fracture toughness values among technical ceramics. Its high thermal expansion and unique resistance to crack propagation make it an excellent material for joining with metals like steel.

Nitrides

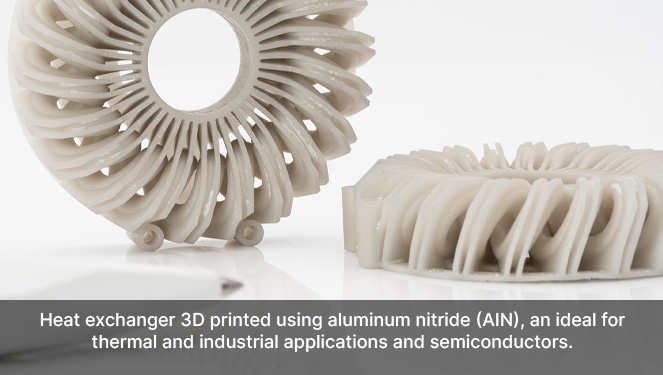

Aluminum Nitride (AlN)*

Aluminum nitride is uniquely suited for thermal management applications as one of the only thermally conductive ceramic materials. It has a coefficient of thermal expansion that is similar to silicon, which, in addition to its high mechanical strength and chemical stability, makes it desirable for use in semiconductor manufacturing.

Silicon Nitride (Si3N4)*

Silicon nitride exhibits many desirable material properties, including high toughness, thermal shock resistance, and corrosion resistance to industrial acids and alkalis. There is growing interest in using this material in orthopaedic implants due to its remarkable antibiofouling and osseointegrative surface properties that support bone growth.

Bioceramics

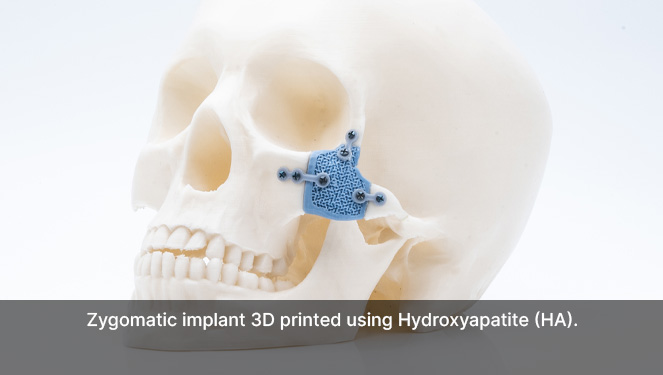

Hydroxyapatite (HA)

Hydroxyapatite is another naturally occurring mineral that forms the main, structural component of bone. HA has excellent biocompatibility and osteoconductivity, making it an optimal material for use in bioresorbable implants with well-defined, porous, and patient-specific geometries. HA is less bioresorbable than TCP, lending itself primarily to scaffolding applications. Once implanted in the body, it provides structural support before allowing bone cells to proliferate through its pore system and eventually replace it.

Development of AM Materials

In addition to established material offerings, Adva Cera works with development partners to continuously explore ceramic photopolymer resin formulations for additive manufacturing. We strive to provide our customers with performance-enabling compositions for increasingly complex applications without compromising on manufacturability.

Disclaimer: Part images on this page are courtesy of Lithoz GmbH