Zirconia (ZrO₂)

A high-performance ceramic material engineered for strength, toughness, and advanced applications.

Adva Cera offers Zirconia (ZrO₂) as a high-performance ceramic material for additive manufacturing applications where toughness, durability, and reliability are critical. Often referred to as ceramic steel, zirconia is valued for its unique combination of mechanical strength, wear resistance, and resistance to crack propagation.

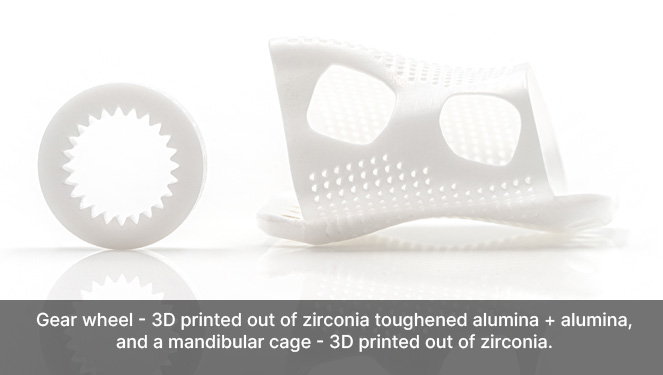

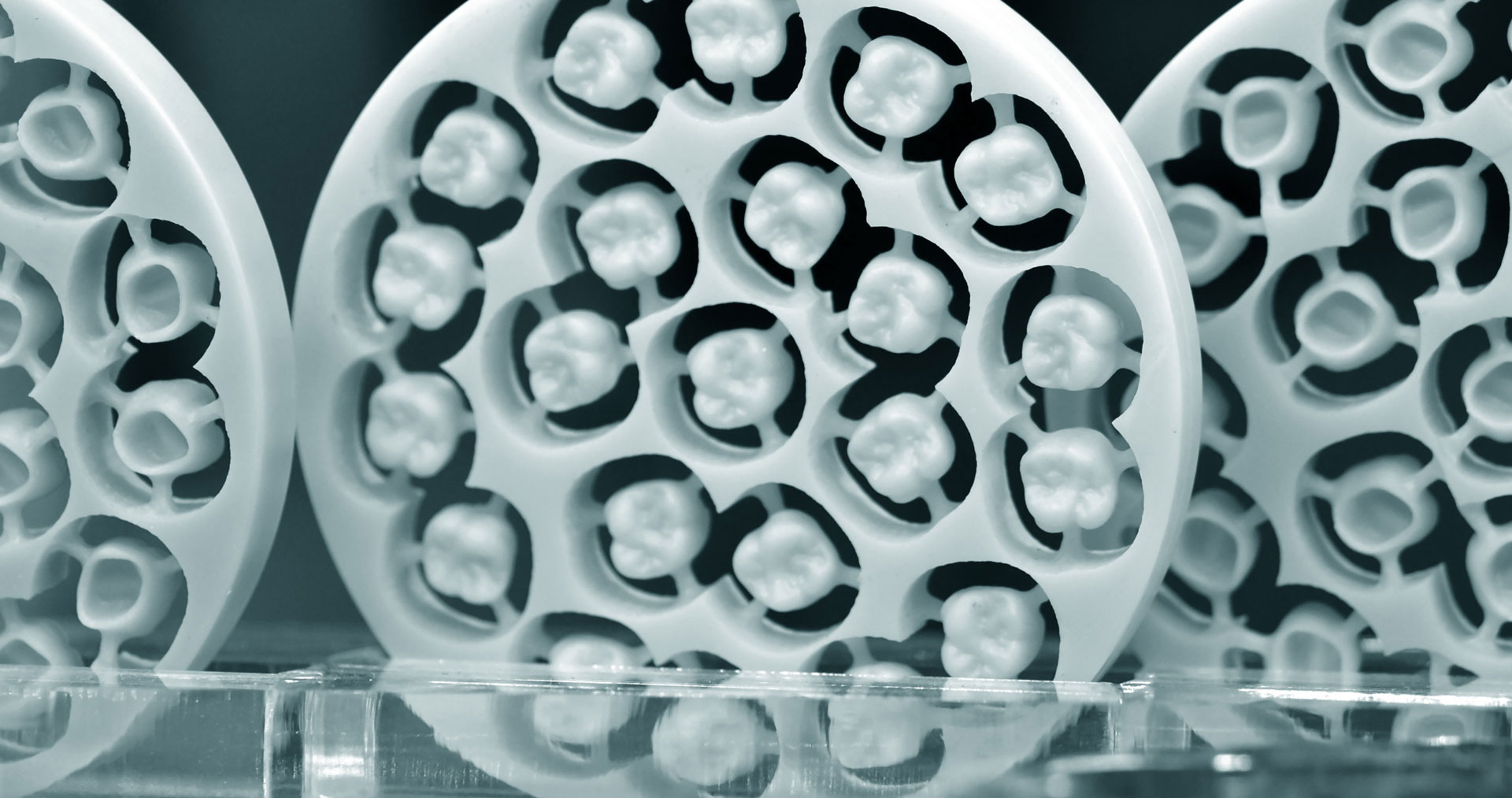

Through ceramic additive manufacturing, Zirconia can be produced in complex geometries while maintaining its exceptional fracture toughness and material integrity. This enables the design of advanced components for demanding industrial, medical, and high-temperature environments.

Zirconia

Material Properties

Zirconia exhibits one of the highest fracture toughness values among ceramic materials, making it particularly well-suited for applications where resistance to cracking and mechanical failure is essential.

Key material attributes include:

These properties allow Zirconia to perform reliably in environments where traditional ceramics may fail.

(303) 449-1457

Why Choose

Zirconia for Additive Manufacturing

Additive manufacturing enables Zirconia components to be produced with complex features, fine details, and optimized designs that are difficult to achieve using conventional manufacturing methods.

Zirconia’s thermal expansion characteristics also make it well-suited for joining with metals such as steel, supporting hybrid assemblies and multi-material designs. Adva Cera’s process integration ensures zirconia parts maintain consistent performance from prototyping through production.

Applications of Zirconia

Due to its strength, toughness, and biocompatibility, Zirconia supports a wide range of applications across industrial and medical sectors.

Typical application areas include:

(303) 449-1457

Design Advantages

With Zirconia

The design freedom enabled by additive manufacturing allows Zirconia components to be tailored for specific performance requirements. Engineers can leverage complex geometries, reduced part count, and application-specific features while preserving the material’s inherent toughness and durability.

Engineering Strength

With Zirconia

By combining advanced material science with ceramic additive manufacturing, Zirconia from Adva Cera enables high-strength, high-toughness solutions for demanding applications. From medical implants to industrial wear components, zirconia remains a critical material for advanced ceramic manufacturing.

Disclaimer: Part images on this page are courtesy of Lithoz GmbH