Nitride Ceramics

High-performance ceramic materials engineered for strength, thermal performance, and demanding applications.

Adva Cera offers advanced Nitride Ceramics developed for additive manufacturing applications requiring exceptional mechanical strength, thermal performance, and reliability. Nitride-based ceramic materials are widely used in environments where components must withstand extreme temperatures, mechanical loads, and chemically aggressive conditions.

Our Nitride Ceramics portfolio supports ceramic additive manufacturing from prototyping through production, enabling complex geometries while maintaining the material properties required for high-performance industrial, electronic, and energy-related applications.

Why Choose

Nitride Ceramics

Nitride Ceramics are valued for their combination of strength, toughness, thermal conductivity, and resistance to wear and corrosion. When paired with additive manufacturing, nitride materials enable advanced component designs while supporting repeatable performance and scalability.

Adva Cera’s integrated approach aligns material formulation, printing, sintering, and validation to ensure nitride ceramic components meet demanding application requirements.

Applications:

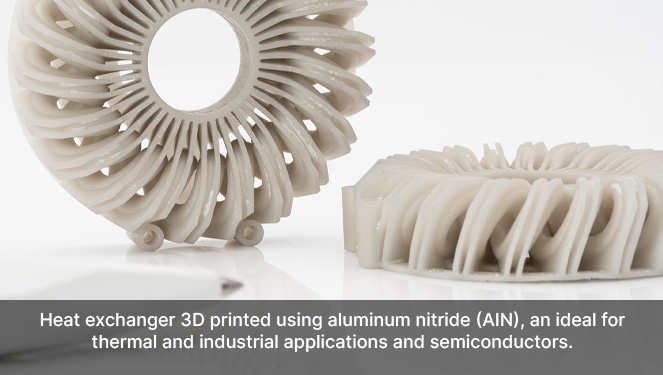

Aluminum Nitride (AlN)

Aluminum Nitride is a specialized Nitride Ceramics material valued for its high thermal conductivity combined with electrical insulation. These characteristics make AlN particularly suitable for applications requiring efficient heat dissipation without electrical interference.

Additive manufacturing enables aluminum nitride components with complex features and tight tolerances, supporting advanced electronic and thermal management applications.

Silicon Nitride (Si3N4)*

Silicon Nitride is a high-performance Nitride Ceramics material known for its excellent mechanical strength, fracture toughness, and resistance to thermal shock. These properties make silicon nitride well-suited for applications involving high temperatures, mechanical stress, and cyclic loading.

Through additive manufacturing, silicon nitride components can be produced with complex geometries and optimized designs while maintaining durability and long service life.

Applications:

Why Choose

Nitride Ceramics Applications

Across industries, Nitride Ceramics support applications where traditional materials are limited by temperature, wear, or mechanical performance. Additive manufacturing expands design flexibility while maintaining the core benefits of nitride-based materials.

(303) 449-1457

Performance-Driven Solutions

With Nitride Ceramics

By combining advanced material science with ceramic additive manufacturing, Nitride Ceramics from Adva Cera enable reliable, high-performance solutions across demanding applications. From structural components to thermal management systems, nitride materials provide the strength and stability required for next-generation designs.

Disclaimer: Part images on this page are courtesy of Lithoz GmbH