Technical Ceramics (Oxides)

High-performance oxide ceramic materials engineered for additive manufacturing and demanding applications.

Adva Cera provides Technical Ceramics based on advanced oxide materials designed for additive manufacturing applications requiring strength, thermal stability, electrical insulation, and durability. Oxide ceramics play a critical role in industries where components must perform reliably under extreme mechanical, thermal, and chemical conditions.

Our Technical Ceramics portfolio includes industry-proven oxide materials optimized for ceramic additive manufacturing, enabling complex geometries, repeatable performance, and scalability from prototyping through production. These materials support a wide range of industrial, aerospace, electronics, and medical applications.

Why Choose

Oxide Technical Ceramics

Oxide-based Technical Ceramics are widely used due to their versatility, stability, and proven performance across many industries. When combined with additive manufacturing, oxide ceramics enable greater design freedom while maintaining the material properties required for demanding environments.

Adva Cera supports oxide ceramic materials engineered for consistency, printability, and post-processing performance.

Applications:

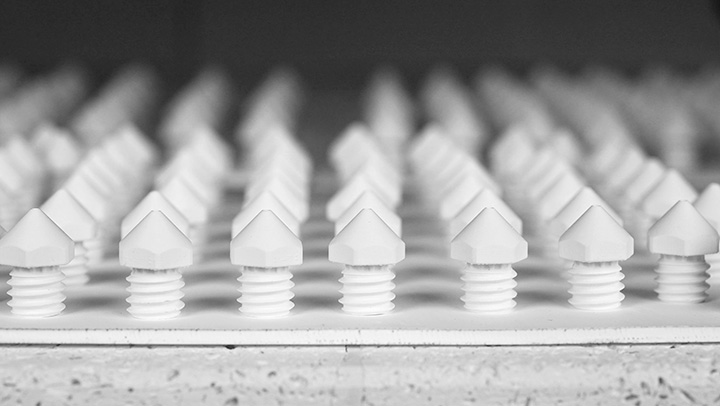

Alumina (Al2O3)

Alumina is one of the most widely used Technical Ceramics and is valued for its high hardness, corrosion resistance, and temperature stability. Alumina components are electrically insulating and puncture-resistant, making them suitable for applications requiring reliability and long-term performance.

Through ceramic additive manufacturing, alumina can be formed into complex geometries while maintaining its mechanical and electrical properties.

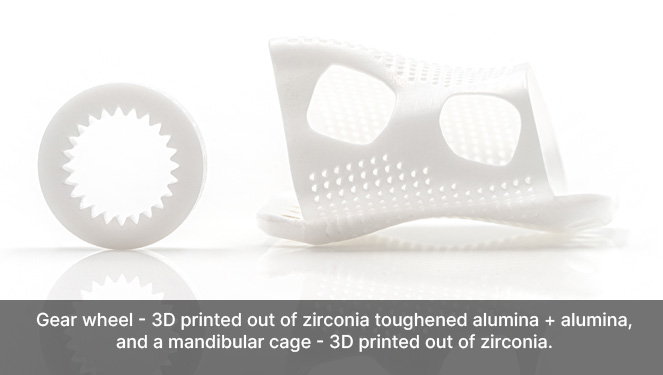

Zirconia (ZrO2)

Zirconia, often referred to as ceramic steel, is a high-performance Technical Ceramics material known for its exceptional fracture toughness, wear resistance, and resistance to crack propagation. Its thermal expansion properties make zirconia particularly well-suited for joining with metals in hybrid assemblies.

Additive manufacturing enables zirconia components with complex features while preserving strength, durability, and biocompatibility.

Applications:

Why Choose

Technical Ceramics Applications

Across industries, Technical Ceramics oxide materials support applications where traditional manufacturing methods are limited. Additive manufacturing enables optimized designs, reduced part count, and application-specific customization.

Primary application areas include:

(303) 449-1457

Engineering Performance

With Technical Ceramics (Oxides)

By combining oxide materials expertise with ceramic additive manufacturing, Technical Ceramics from Adva Cera enable reliable, high-performance solutions across a broad range of applications. Our oxide ceramic materials are engineered to support innovation today while scaling for tomorrow’s production needs.

Disclaimer: Part images on this page are courtesy of Lithoz GmbH